THE SCIENCE BEHIND DREAMGLASS®

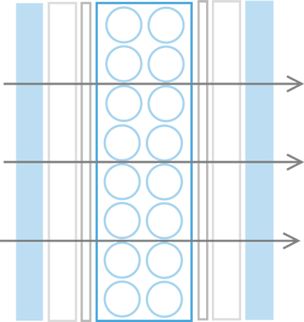

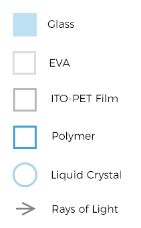

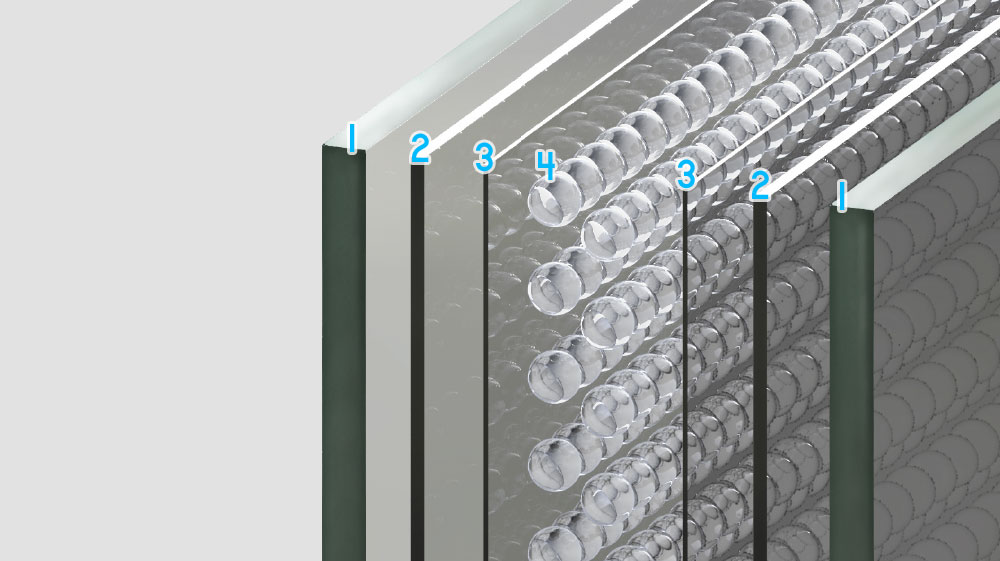

DreamGlass® is composed of a thin film interlayer of liquid crystals dispersed in a polymer matrix (PDLCs) laminated between two plastic substrates coated on the inner face with a thin layer of conductive material. By applying a small electrical current, its state can change from opaque to transparent and vice versa. EVA is used to bond the thin film with the glass.

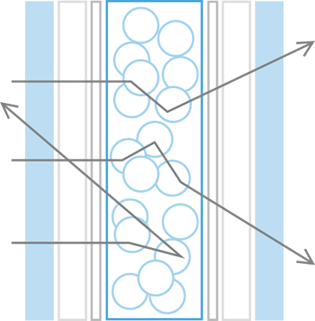

This ingenious smart glass technology allows you to switch back and forth between opaque glass and a transparent view, all through a simple electrical current. DreamGlass® panels contain a film of dispersed liquid crystal molecules in a polymer matrix pressed between two glass sheets. When an electrical current activates the panel, the liquid crystal molecules instantly align. This positioning allows light to pass through, and your glass becomes transparent. When the current is disconnected, the molecules immediately disarrange for instantaneous and total privacy.

Power On

The liquid crystal molecules align and light can pass through.

Power Off

The liquid crystal molecules are randomly aligned making light scatter and the glass opaque.

- 1Glass

Choose the desired thickness, type, shape, and color. - 2EVA

A cross-linked transparent sheet which acts as a bond between the glass and ITO-PET laminate. - 3ITO-PET

A transparent conductive film of only a few microns in thickness. - 4Liquid Crystal Polymer Matrix

A pool of randomly orientated liquid crystal molecules. When stimulated with electrical current, the liquid crystal molecules align themselves allowing incident light to pass through, thus the glass becomes clear.

DreamGlass® Technical DATA

The figures below are recommended for guide purposes only. Dream Glass Group reserves the right to amend information without prior notice.

ENVIRONMENT:

ENVIRONMENT:

Storage:

Operation:

-20°C to 70°C

-10°C to 60°C

Electrical Properties:

Electrical Properties:

Operating Voltage:

Operating Frequency:

Power Consumption:

Switching Time:

60 to 65V AC

50 to 60 Hz

< 10W / m2

< 0.1 seconds

OPTICAL PROPERTIES:

OPTICAL PROPERTIES:

Total Transmitance OFF state:

Direct Transmitance OFF state:

Transmitance ON state:

Haze On State

62% +/- 2%

0.4%

> 78%

< 4.5%

SOUND CONTROL DATA:

SOUND CONTROL DATA:

Thickness:

4 + 4 mm

5 + 5 mm

6 + 6 mm

8 + 8 mm

Custom Configurations

Glazing

Bullet Proof

Standard Construction:

4mm low iron glass + 0.4mm EVA + PDLC + 0.4mm EVA + 4mm low iron glass

5mm low iron glass + 0.4mm EVA + PDLC + 0.4mm EVA + 5mm low iron glass

6mm low iron glass + 0.4mm EVA + PDLC + 0.4mm EVA + 6mm low iron glass

8mm low iron glass + 0,4mm EVA + PDLC + 0,4mm EVA + 8mm low iron glass

non standard compositions

standard double glazed units or triple glazed units

combinations of DreamGlass® with bullet proof glass and interlayers

DB Rating (RW):

36

37

38

39

subject to composition

subject to composition

subject to composition

PHYSICAL PROPERTIES:

PHYSICAL PROPERTIES:

Thickness:

4 + 4 mm

5 + 5 mm

6 + 6 mm

8 + 8 mm

Custom Configurations

Glazing

Bullet Proof

Standard Construction:

4mm low iron glass + 0.4mm EVA + PDLC + 0.4mm EVA + 4mm low iron glass

5mm low iron glass + 0.4mm EVA + PDLC + 0.4mm EVA + 5mm low iron glass

6mm low iron glass + 0.4mm EVA + PDLC + 0.4mm EVA + 6mm low iron glass

8mm low iron glass + 0,4mm EVA + PDLC + 0,4mm EVA + 8mm low iron glass

non standard compositions

standard double glazed units or triple glazed units

combinations of DreamGlass® with bullet proof glass and interlayers

Haze:

< 5%

< 5%

< 5%

< 5%

< 5%

< 5%

< 5%

UV Protection

> 98%

> 98%

> 98%

> 98%

> 98%

> 98%

> 98%

![]() DESIGN OPTIONS:

DESIGN OPTIONS:

| Thickness: | Curved | Shaped | Sand Blasted | Screen Printed | Patterned |

|---|---|---|---|---|---|

| 4 + 4 mm |  |

|

|

|

|

| 5 + 5 mm |  |

|

|

|

|

| 6 + 6 mm |  |

|

|

|

|

| 8 + 8 mm |  |

|

|

|

|

| Custom Configurations |  |

|

|

|

|

| Double/Triple Glazing |  |

|

|

|

|

| Bullet Proof |  |

|

|

|

|

![]() CERTIFICATIONS:

CERTIFICATIONS:

| Thickness: | CE | ISO 9001:2015 | ISO 10140-2:2011 | IPX7 |

|---|---|---|---|---|

| 4 + 4 mm |  |

|

|

|

| 5 + 5 mm |  |

|

|

|

| 6 + 6 mm |  |

|

|

|

| 8 + 8 mm |  |

|

|

|

| Custom Configurations |  |

|

optional | optional |

| Double/Triple Glazing |  |

|

optional | optional |

| Bullet Proof |  |

|

optional | optional |